|

Mechanical Shock Testing Machine ZH-30CJ400

Telephone:+86 13794880254

Mail:carleen@sailham.com

|

Mechanical Shock Testing Machine

ZH-30CJ400

1. Technical data solution

1.1. Product application.

The CJ series mechanical shock testing machine is mainly suitable for impact resistance testing in electronic products, aerospace, shipbuilding, military, automotive components, transportation and other fields. By selecting different waveform generators, impact tests such as half sine wave, back peak sawtooth wave, or square wave can be conducted.

The equipment meets the following requirements: GB/T2423-2008, GJB150, GJB360, GJB548, GJB1217, MIL-STD-202F, IEC-68-2-27, MIL-STD-810F, MIL-STD-883E etc..

Structural schematic diagram of CJ series impact testing system

Comparison table of peak acceleration and pulse duration

Peak acceleration A(gn) | 5 | 15 | 30 | 30 | 30 | 50 | 50 | 100 | 100 | 200 | 200 | 500 | 1000 | 1500 | 3000 |

Pulse duration D(ms) | 30 | 11 | 18 | 11 | 6 | 11 | 3 | 11 | 6 | 6 | 3 | 1 | 1 | 0.5 | 0.2 |

1.2. Main performance.

1.2.1. The free fall impact machine adopts hydraulic lifting and high-pressure hydraulic braking,

1.2.2. Adopting gas-liquid pressurization and strong friction brake to prevent secondary impact braking function;

1.2.3. Impact measuring instrument: Single channel data acquisition, capable of measuring, storing, printing reports, retrieving data, and managing databases for acceleration data from two channels simultaneously.

1.2.4. Using rubber modules, generate a wide range of half sine wave pulses with arbitrary action time.

1.2.5. Can be used as an equivalent drop test for packaging boxes.

1.3. Configuration list.

No | Item | Model | Quantity |

1 | Shock impact table | CJ30 | 1 set |

2 | Hydraulic lifting mechanism | 1 set | |

3 | controller | SKC-1 | 1 set |

4 | Impact measuring instrument | ST-2 | 1 set |

5 | Sensor | Sailham | 1PC |

6 | Computer | Lenovo | 1 set |

7 | Waveform Generator | Single group semi sine | 1 set |

Rear peak sawtooth wave (optional) | 1 set | ||

Square wave (optional) | 1 set | ||

8 | Safety device | Sound and light safety alarm | 1 set |

9 | Accessories to machine | Tools, fixtures/manuals, installation CDs, etc | 1 set |

2. Technical parameters

Main technical parameters. | |

Working platform | 400×400 mm (other space can be customized) |

Maximum Load | 30KG (other load can be customized) |

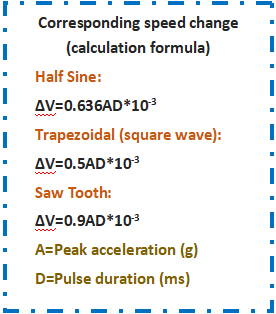

peak acceleration | Half sine wave 20-1000G |

Pulse Duration | Half sine: 1-30ms |

Acceleration tolerance | ≤ 10% |

Speed variation | ≤ 10% |

Horizontal ratio of countertop | ≤ 10% |

Equipment size | 1230×1120×2330mm appr. |

Total equipment quantity | 1750 kg |

Measure systems | |

Channel | 2 Channels |

Sampling frequency | 192KHz |

Pulse Duration | 0.5-100ms |

Maximum acceleration | 5000G |

Communication interface | USB 2.0 |

Supported Standards | ISO, MIL-STD-810, user customized |

Operating system | Microsoft Win10 |

System acceleration sensor | |

Brand | Sailham |

Model | 22100 |

Output | Charge type |

sensitivity | 3.93pC/g |

Frequency range | 0.5 -- 12KHz |

Acceleration range | ±2500G |

work environment | -40~+160℃ |

Others | |

Power supply | AC 3 phase 380V ± 10% 5KVA |

Compressed air | 0.5-0.8Mpa |

Temperature | RT~40℃ |

Humidity | 25℃<85RH% |

Reliability | The average fault free rate is ≥ 5000 hours; The half sine waveform generator should be used continuously for no less than 8000 times and stored for no less than 5 years in a clean and room temperature environment. |

Reliability | GB2423.5, GJB150.18, GJB360.23, IEC68-2-27 , MIL STD202F, MIL-STD810B, GB/T18287 etc.. |

Standards | JG541-2005 |

Phone

+86 13794880254

carleen@sailham.com

Applets

Mobile station

Mobile station QR code