|

Altitude Test Chamber ZH-LP-50A

Telephone:+86 13794880254

Mail:carleen@sailham.com

|

Altitude Test Chamber

ZH-LP-50A

1. Function.

1) Battery low pressure (high altitude) simulation test chamber, all tested samples are tested under negative pressure of 11.6kPa (1.68psi). The ambient temperature is stored at 20 ± 5 ℃(Control ambient temperature by air conditioner, no temperature control in the box) for 6 hours, if the battery has no leakage , no exhaust, no disintegration, no rupture and no fire, and the open circuit voltage of each experimental cell or battery after the test is not less than 90% of the voltage before the simulation test, which is qualified.

2) It’s designed for UL, IEC, UN, GB and other standard test requirements, to reach the low pressure storage state of the sample in a short period of time, can automatically control the test cycle, monitor the pressure change in the chamber throughout the process, and automatically terminate the test purpose;

3) High altitude simulation test, all tested samples are tested under low pressure.

2. Purpose.

1) The final test results require that the battery cannot explode or catch fire; in addition, the battery cannot smoke or leak, and the battery protection valve cannot be damaged.

2) Test whether other electronic and electrical products can work normally under low voltage, or be damaged.

3. Conforms to the standard

1) Meet the standard: UN 38.3 / UL 1642 / IEC62133 / UL2054 / GB 31241

4. Specification.

1) Internal dimensions: 500 x 500 x 500 mm (125L); (Other sizes are available)

2) External dimensions appr: W720 x D690 x H1750 mm, subject to the actual product;

3) Inter layer: The inner box is divided into two layers, the first layer is 50 mm from the bottom, and the above is divided equally, with 2 sample shelves;

4) Door opening method: single door is opened from right to left;

5) Visible window: with visible window on the door, the whole piece of 19 mm thick tempered glass, size: W200 * H250mm;

6) Internal material: stainless steel industrial plate thickness is 1.5 mm, internal strengthening treatment, no deformation after vacuuming;

7) External material: cold-rolled Q235 steel plate, 1.0 mm thick, powder paint treatment; (off-white)

8) Hollow filling material: rock wool, good thermal insulation effect;

9) Door sealing material: high temperature resistant silicone strip;

10) Casters: Install movable casters and fixed feet cups, which can be fixed in position and pushed at will;

11) Control panel: The control panel is installed above the machine;

12) Structure: integrated; (pictured or design drawing)

13) Vacuum pump installation: The vacuum pump is installed on the upper part of the machine.

5. Vacuum system.

1) Sealing: The machine adopts high-density silicone sealing strip to seal at the door;

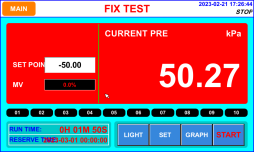

2) Pressure gauge: touch screen controller is used to display the instantaneous barometric pressure in the box; (pictured)

Pressure gauge Pressure sensor

3) Air pressure sensor: adopt diffused silicon pressure transmitter; (pictured)

4) Timing function: pressure keeping time, if you need to keep the pressure control after reaching the set pressure, just open the timer, the pressure will be automatically released after the time is up, the alarm will prompt after the pressure is completed, and closed if not needed;

5) Air pressure control method: automatic control type, it will automatically stop when starting pumping to reach the set value, and automatically start when it is lower than the lower limit, so as to work cyclically to compensate for leaking air pressure;

6) Pressure relief method: automatic pressure relief after the test, manual pressure relief when taking the product during relief process;

7) Air pressure range: 5.0KPa to 101.3KPa, absolute air pressure display, different air pressure display in different regions;

8) Air leakage rate: ±0.5KPa (5.0KPa~40KPa), ±1.0KPa (41KPa~80KPa)

9) Pressure display accuracy: 0.1Kpa

10) A11. Vacuum pressure leakage rate: Stop the vacuum pump when the vacuum reaches 5.0KPa, and maintain the pressure for 24 hours with a leakage rate of ≤ 15KPa;

11) Vacuum pump configuration: Dalton VP550 vacuum pump with a power of 220V/0.55KW (As shown in the figure)

6. Power supply source.

l Voltage: 220V, 50Hz, single phase

l Current: 6.8A

l Total power: 1.5KW

l Circuit protection system: ground protection, fast insurance, motor overload, etc.

Phone

+86 13794880254

carleen@sailham.com

Applets

Mobile station

Mobile station QR code