|

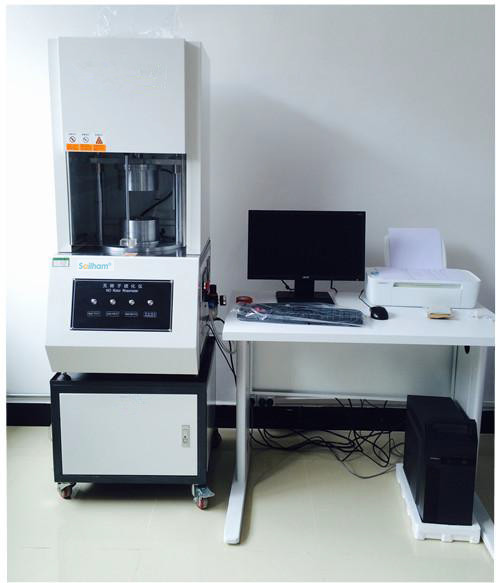

Rotorless RheometerZH-8001A Rotorless rheometer is the instruments used most widely for the rubber processing industry to control the quality, basic research and application for rapid inspection, it’s used for the rubber formulation of the most optimized combination to get accurate data, can accurately measure the scorch time, positive Vulcanizer time, vulcanization index and the maximum and minimum torque and other parameters.

Telephone:+86 13794880254

Mail:carleen@sailham.com

|

ZH-8001A Rotorless rheometer is the instruments used most widely for the rubber processing industry to control the quality, basic research and application for rapid inspection, it’s used for the rubber formulation of the most optimized combination to get accurate data, can accurately measure the scorch time, positive Vulcanizer time, vulcanization index and the maximum and minimum torque and other parameters.

Main parameters.

Model | ZH-8001A |

Temperature control range | RT ~ 200℃ |

Temp. fluctuation | ±0.15℃ |

Torque resolution | 1/500000 |

Torque accuracy | 0.3% |

Torque unit | N.m, N.cm, N.inch, kN.m, kN.cm, kN.inch, kg.m, kg.cm, kg.inch, lp.m, lp.cm, lp.inch, gm, g. cm, g.inch |

Temperature display resolution | 0.01℃ |

Mold recovery temperature recovery time | < 1.5min |

Temperature unit | C (degrees Celsius), F (degrees Fahrenheit), K (Kelvin) |

Acquisition rate | 200 times / S |

Support language | English, Simplified Chinese, Traditional Chinese. |

Use standard | GB/T 16584, ASTM D5289, ISO 6502 |

Calculate parameters | ts1, ts2, t10, t30, t50, t70, t90, Vc1, Vc2 |

Software interface | USB2.0 |

Print content | Date, time, temperature, vulcanization curve, temperature curve, ML, MH, ts1, ts2, t10, t50, t90, Vc1, Vc2 |

Test Standard | According to ASTM D 5289, ISO6502 |

Oscillation frequency | 100 cycles per minute (1.67Hz) |

Oscillation amplitude | Standard: ± 1 ℃ ± 0.03 ℃ |

[Optional] ± 0.5 ℃ ± 0.03 ℃, ± 3 ℃ ± 0.03 ℃ | |

Temp. changing time | 170℃→ 190℃: keep ± 0.3℃ within 55 seconds 190℃→ 170℃: to reach and keep±0.3℃within 1min 40 s |

Temp. recovery time after mold closed | Temperature compensation back to the set temperature of 170 ℃ (error within ± 0.3 ℃) does not exceed 30 ± 3 seconds |

Temp. heating rate | RT→170℃ to reach and keep±0.3℃ within 2 min 40 seconds |

Power supply Air pressure source | 220VAC±10%, 50±3Hz; minimum 65psi (4.5kg/cm2) |

Size | L65cm x W59cmx H148cm |

Weight | 250kg |

Phone

+86 13794880254

carleen@sailham.com

Applets

Mobile station

Mobile station QR code